A pressure vessel is a closed container designed to hold gases or liquids at a pressure that is substantially different from the ambient pressure. Types of pressure vessels vary according to their function and may include storage tanks, boilers, heat exchangers and process vessels.

Most pressure vessels are designed so that all components can withstand the worst-case combination of vapour pressure and static pressure, which is determined at the bottom of the vessel.

The repercussions of a pressure vessel failure are a combination of loss of containment, fire and a potential explosion which could have serious effect on the people and plant in the surrounding area.

Given these dangers, pressure vessel design, manufacture, and operation are regulated by legislation backed by Engineering Standards and Regulations.

So, for an Australian business, how do you know if your application requires a product to be a pressure vessel?

Generally, a process engineer will assemble information on a range of design parameters such as design pressures, design temperatures, tank inside diameter, operating volume, vessel content information, installation site location etc. Typically, the operating pressure of the vessel will have some uncertainty in it, so margins are applied to ensure the safety of the design. The vessel is assumed to operate, for calculation purposes, up to a design pressure of approximately 10-15% above the maximum expected operating pressure.

Armed with this information, design engineers would determine whether the proposed application requires a pressure vessel, using the requirements of AS 1210 – Pressure Vessels.

AS 1210 provides:

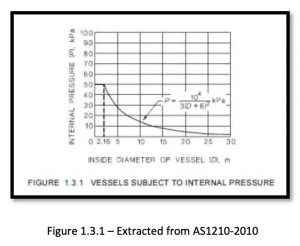

- Internal pressure envelope that has a lower limit of P = 10^4 / [3(D+6)^2] kPa.g, and no upper limit, where D, the internal diameter, is measured in metres and has a limit of 30m.

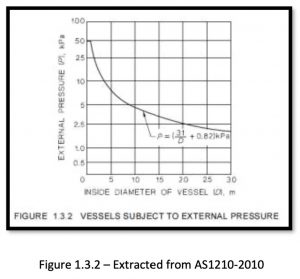

- External pressure envelope that has a lower limit of P = (31/D) + 0.82 kPa.g and no upper limit, where D, the internal diameter, is measured in metres and has a limit of 30m.

Example calculation to check if a given vessel is a pressure vessel

Given Data:

- D = 3.4m

- Design Internal Pressure (Pint) = +300 kPa

- Design External Pressure (Pext) = -10 kPa

Check 1: External Pressure

P1 = 10^4 / [3(D+6)^2] = 37.7 kPa

If Pint is greater than P1, the vessel is considered a pressure vessel

Check 2: External Pressure

P2 = (31/D) + 0.82 = 9.94 kPa

If Pext is greater than P2, the vessel is considered as pressure vessel

The design pressure need only exceed P1 or P2 for the vessel to be considered as pressure vessel. In AS 1210, for ease, these calculations are summarised as charts in sections 1.3.1 and 1.3.2.

Steps in Designing Pressure Vessel:

- Gather design parameters such as design pressures, design temperatures, tank inside diameter, operating volume, vessel content information, installation site location etc;

- Check if vessel is a pressure vessel using AS1210;

- Carry out hazard level identification using the following parameters to identify if the vessel requires third-party design verification and plant design registration;

- Fluid Type

- Vessel Total Volume

- Design Pressure

- Design Temperature

- Installation Site Location and Condition

Regulatory bodies such as SafeWork NSW and WorkSafe Victoria provides regulations for pressure equipment in Australia.

- Decide the class of construction that is to be used. This will have an impact on weld joint efficiency which is used in vessel wall thickness calculation. The level of required examination and testing varies for the different classes of construction.

All vessel classes must be manufactured as per AS 4458 and welding procedures and qualifications as per AS/NZS 3992. Vessel examination and testing must be carried out as per AS 4037. 2. Design the vessel wall thicknesses as per AS1210 formulas.

- Design the vessel wall thicknesses as per AS1210 formulas.

- Design the vessel to withstand environmental loads as per AS1170.

——-

Headquartered in Griffith, NSW, A&G Engineering is an Australian, family-owned company that has grown from humble beginnings in 1963 to become Australia’s leading designer and fabricator of stainless-steel tanks and pressure vessels. The unmatched combination of experience, flexibility, expertise, and technology for every A&G project serve to minimise production risk and ensure on-time, on-budget, and as-specified delivery.

Ready to find out how A&G can help you on your next project? Talk to our expert team by calling us on (02) 6964 3422 or email sales@agengineering.com.au with your inquiry. We look forward to hearing from you.