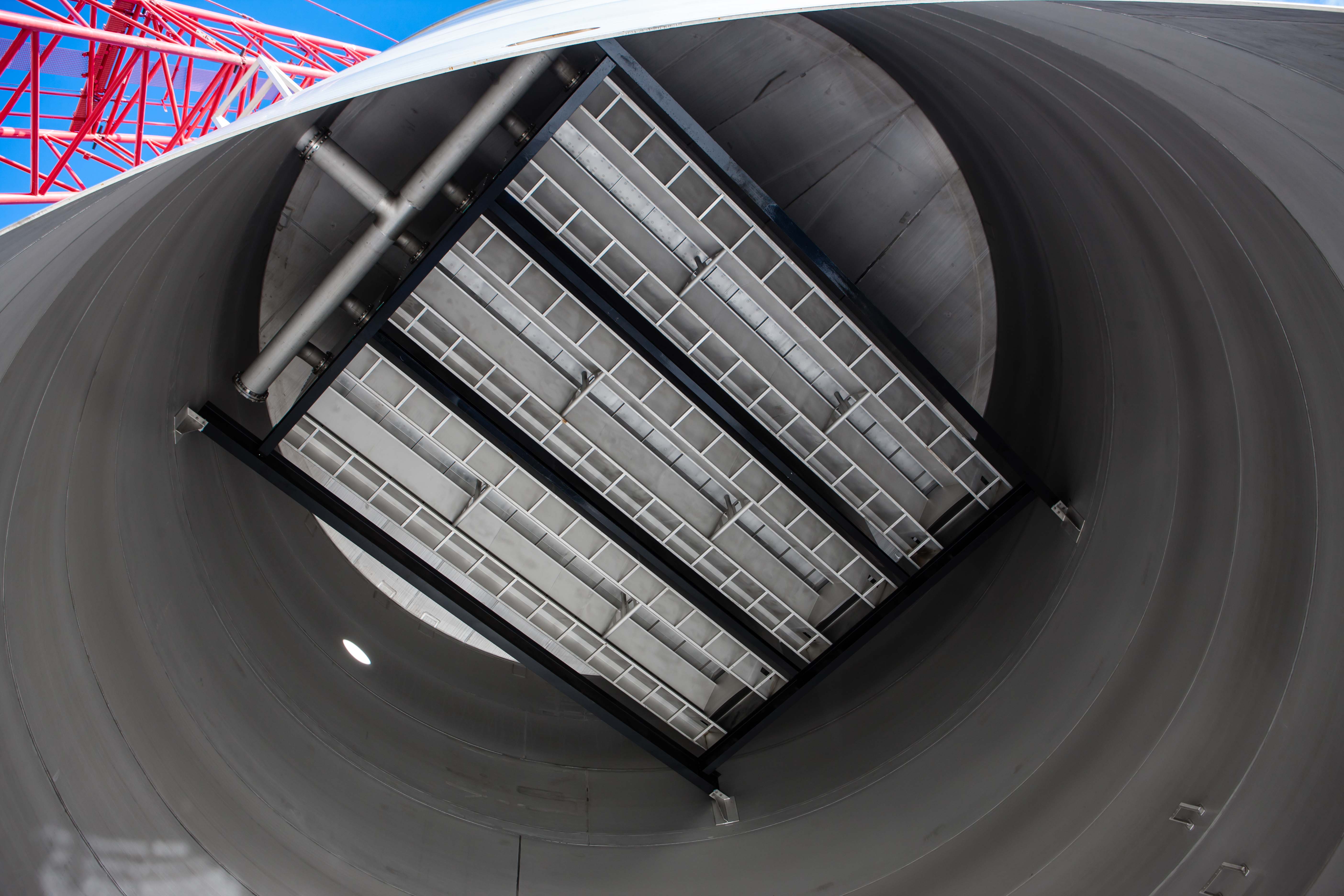

Our customers in various sectors and across Australia have stainless steel tank requirements for the storage, blending and mixing of industrial chemicals.

Whether you’re looking for vertical, horizontal, square or dual skin tanks, we supply overhead and gravity-fed options and also offer associated dispensing, metering and fill equipment. Our insulated tanks are designed to comply with evaporation reduction and fire-rating requirements.

A&G’s stainless steel storage tanks for industrial chemicals include:

- Compliance with Industry Standards API 620, API 650, EN 14105

- Storage of substances such as: ammonia, aluminium sulphate, nitric acid, sodium hydroxide, peroxide, resin, glycol and for desulphurization

- Transportable standard tanks or custom builds from 500 to 350,000 litres, or up to 5 million litres on-site fabrication

- Configurations: vertical, horizontal, square, dual skin

Awarded expertise in design, fabrication and installation of stainless steel equipment for primary industries, petrochemical and mining operations across Australia.

A&G Engineering – 50 years awarded expertise in design, fabrication and installation of stainless steel equipment for primary industries, food and beverage, and mining operations across Australia.

A&G guarantees professional excellence as your quality stainless steel partner. We’re here to help you meet the constraints of time, site, space and delivery.

Value adding:

- Low TCO – our steel tanks and pressure vessels, up to 5 million litres, built for low total cost of ownership

- Design features focus on safety and ease of use for minimised manual input and downtime

- Rapid, de-risked deliveries using A&G’s professional transport and installation teams

- Help with re-sale and relocation of redundant equipment